Today’s Signage 101 post will discuss the pros and cons of direct printing versus vinyl overlays for rigid signs. Common rigid signs include aluminum signs, plastic signs, and acrylic signs. We’ll compare each method to help you decide which is best for you. As a rule of thumb, vinyl overlay works best as temporary signage. Direct printing best suites permanent, high-resolution signage.

What is a Vinyl Overlay?

A vinyl overlay is a vinyl sheet with either a printed design or solid color, adhered to a rigid material. These overlays offer a cheaper alternative to smaller sign shops who often can’t afford large, flatbed printers.

Vinyl Overlay Advantages

Vinyl overlays work best for temporary signs. The ease of removing and replacing the overlay makes them ideal in scenarios where information constantly changes. For example, an exterior aluminum sign outlining store hours or parking regulations benefits from the advantage of simply printing a new vinyl overlay and replacing the old one.

Removing and replacing vinyl overlays requires a razor blade, cleaner, non-abrasive brush, etc. After removing residue from the rigid portion of the sign, update the sign for only the cost of printing new vinyl overlay. That makes vinyl overlays a versatile, semi-permanent solution for a variety of uses and situations.

Vinyl Overlay Disadvantages

Installation and Removal

The overlay’s versatility also creates some disadvantages. Anyone who has installed a sticker or decal of any type knows it’s easy to run into issues during application. That could mean tearing the material when removing its backing or unwanted bubbles and lines during application. There’s also the risk of damaging corners or edges from handling, which leads to peeling and weakens the adhesive. Considering all of this, working with vinyl overlay can mean a lot of headaches.

That said, carefully following installation instructions can help prevent air bubbles or pockets. Doing so will require some sweat equity and a knowledge of appropriate tools and cleaners to use. Keep in mind, some of the rigid materials used for displaying the vinyl overlay may not be strong enough to withstand the vigorous scrubbing needed for removing residue, and may scuff or scratch when replacing new vinyl overlays.

Peeling Possibility

An exterior sign using a vinyl overlay may not hold up against weather and the elements. Over time, the adhesive will weaken and the overlay will begin to peel off, significantly diminishing the quality of your sign. Another scenario is intentional damage or removal of the vinyl overlay by passersby that deface the sign. Much like any externally placed sticker or decal, this risk will always be present. A person or group of people determined to deface, damage or destroy signage only need to peel up a corner and remove the vinyl all together. While this disadvantage pertains to vinyl overlay, where someone intends intentional damage, any sign faces the risk of vandalism.

What is Direct Printing?

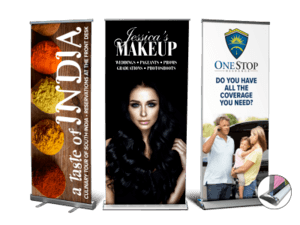

Direct printing means that the sign manufacturer prints your design or logo directly onto the surface of the sign. This print method is standard when printing on non-rigid materials such as vinyl banners, and is considered a superior method over vinyl overlay for creating rigid signs. At Signs.com direct print comes standard on all of our products, with the exception of our vinyl lettering and wall graphics, and our aluminum signs. Though we do not offer signage that incorporates vinyl overlays, we do offer clear vinyl signage that can be placed on a variety of substrates. Clear window decals can give the effect of a vinyl overlay, as well as our backlit decals and vinyl lettering.

Direct Printing Advantages

Direct printing offers a number of advantages over vinyl overlay. Primarily, with no layer in between the substrate and the design, direct printing offers vivid, crisp reproduction of text and images. While vinyl overlays can reproduce high resolution image (assuming the original file is a high resolution or vector image) it won’t be as sharp or vibrant as direct printing.

Another advantage is the durability of the ink and the sign. Signs.com prints with UV inks that provide a durable, fade and scratch resistant finish to your sign. These inks are rated for outdoor use and can last for years with proper sign care and maintenance. That means more protection against loss of adhesion or peeling since this method cures the ink directly onto the surface. However, even direct surface printing is susceptible to scratching and other damage caused by sharp objects or intentional abuse.

Direct Printing Disadvantages

Permanence of Design

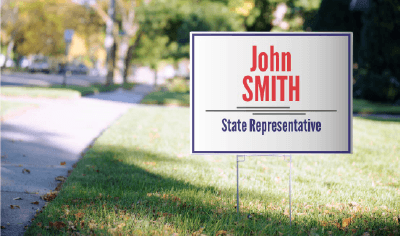

Unlike with vinyl overlay, direct printing will be permanent. As mentioned above, vinyl overlays enable reuse of the rigid material when updating sign information. Direct printing, unfortunately, doesn’t offer that benefit. Having said this, we’ve found that rigid materials such as aluminum, brushed aluminum and rigid plastic signs are best when intended for long-term use.

These are signs that are placed outdoors and expected to last for a long time. So, the inability to change the messaging of the sign usually isn’t necessary. Even other rigid signs that are used for shorter durations (foamboard and corrugated yard signs) result in more affordable signage by printing directly to the surface of the material rather than adding in the cost of the vinyl overlay and the installation labor on top of the material cost.

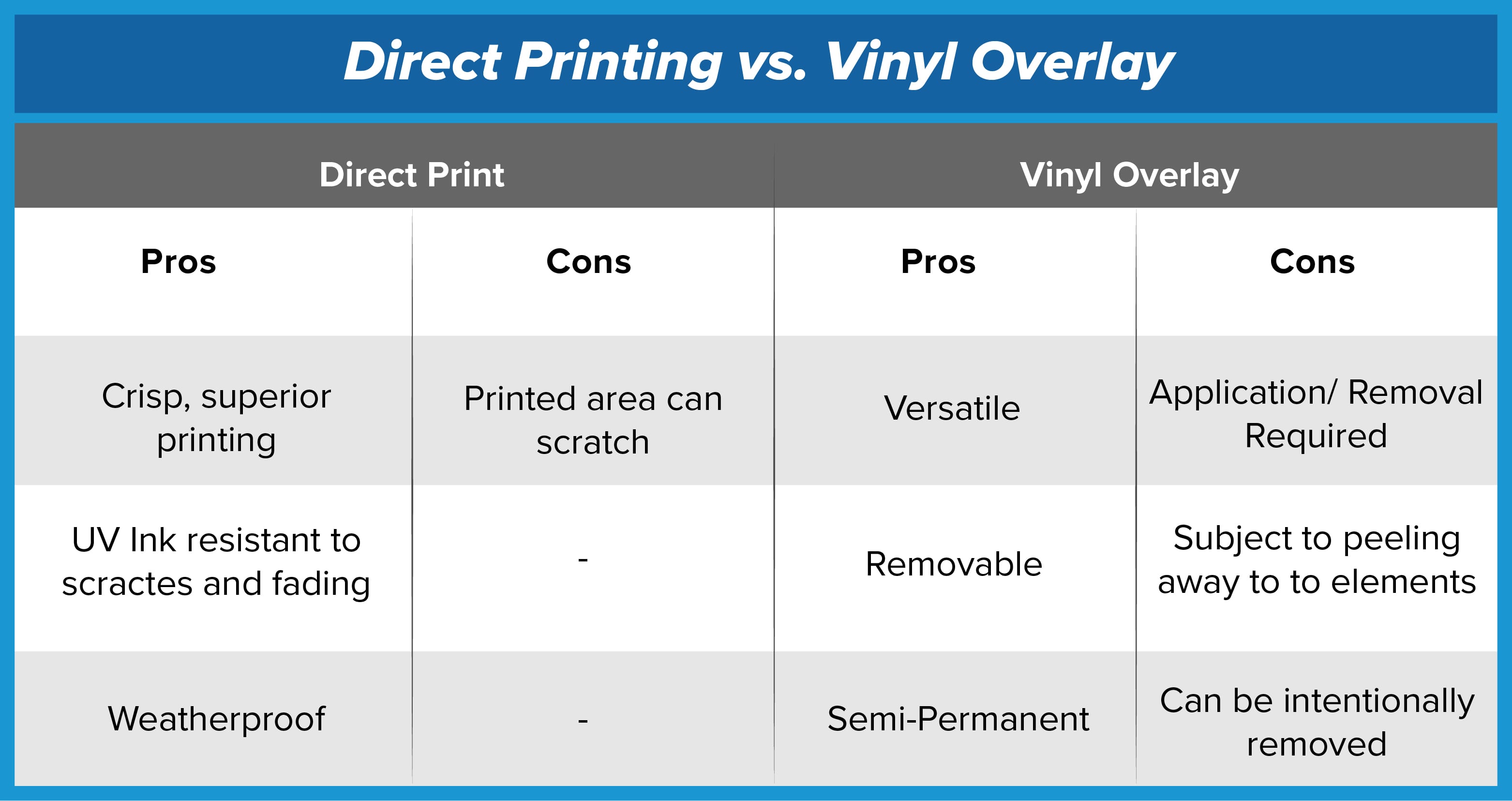

So there you have it; those are the differences of directly printing onto a material versus using a vinyl overlay. If you’re still trying to conceptualize everything, the charts below will help show the pros and cons of each process. If you have any other questions about your signage, feel free to give us a call at 888-222-4929, or shoot us an email at support@signs.com!

Watch this video about our aluminum signs to see the advantage of direct printing using digital UV ink: