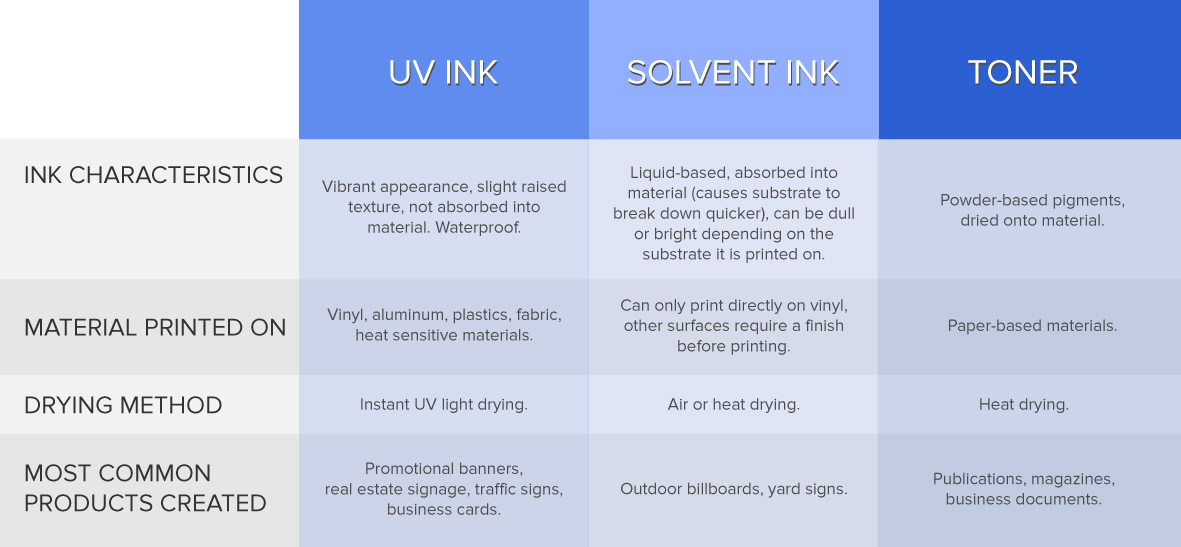

Giving your sign a lasting, eye-catching design is a top priority for us at Signs.com. To assist in fulfilling your design desires, we incorporate specialized ink to create visually stunning signs. Ink is more complex than it may seem; inks come in either a solid, powder, or aqueous (liquid) form. You’re most likely familiar with the liquid form of ink, which is found in pens and consumer-based inkjet printers. The solid or paste inks are typically found in industrial UV printers. Powder based inks, also known as toner, are used in consumer and industrial laser printers.

What do we use? The majority of our signs are printed using UV ink, which produces high quality and permanent designs. We’ll give you an overview of all three types of ink: UV, solvent and toner, showing you how each are used and why we choose to implement UV inks in producing your custom signage.

UV Ink

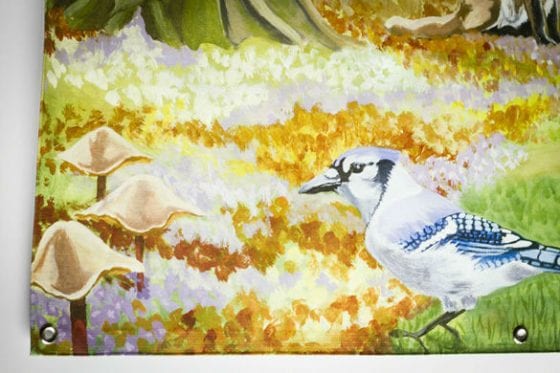

Modern technology has provided the printing industry with a state of the art printing process that allows for vibrant ink to cure instantly on virtually any substrate (just a fancy word for the surface or material). UV ink, which is implemented in UV printing, results in a crystal clear printed design. The vibrance of the ink is achieved due to the instant curing of the ink as soon as it is printed on a material. Instead of being absorbed into the material, which occurs when inks are heat or air dried, UV ink cures on the surface. Due to surface curing, ink will have a matte appearance and a slight texture to it. Colors can also become faded or not as true when absorbed or evaporated into the air, which UV ink prevents from occurring. UV ink is also scratch, abrasion, and weather resistant.

UV ink is eco-friendly and does not contain volatile organic compounds (VOC). This ink has the ability to print in true color, meaning that colors can be matched using a standard set of Pantone colors. Check out this crash course on why colors matter in the printing process! White ink can be printed using UV ink, which helps colors stick out on darker or clear materials. Heat sensitive materials also benefit from the UV drying, as UV light does not give off heat during the printing process.

Instant curing of the ink allows for printing on a variety of surfaces. At Signs.com, we use UV ink when printing on our vinyl banners, aluminum signs, rigid plastic signs, clear window decals, and most every other product we offer. If you’re wondering what type of ink is used in your sign, each of our product pages includes the printing method and the ink used to create your design.

Solvent Ink

One of the most commonly used inks in the printing industry is solvent ink. Solvent ink is comprised of a fluid (water or liquid base), pigment (color), and a resin (adherent), which results in a durable, long lasting ink. Unlike UV ink, solvent ink cures with either air or heat application. Because solvent ink air dries, ink could dry within the printing heads, clogging the machine and causing your design to print wrong. Frequent cleaning of the heads will prevent this from occurring. This additional maintenance can also cause downtime of printers and increased costs which many printers pass onto their customers in the form of higher costs or longer turnaround times.

Ink that is absorbed into the substrate may also dull the colors compared to ink that is dried on the surface. Though colors may dull, absorption into a material gives excellent resistance against weather and scratching. Ink absorption allows for materials to bend without stretching or cracking of the ink. There is no need for special coatings or laminates to protect the ink when it is printed.

Solvent based inks do allow for a smaller dot size when printing, providing gradients (variations) in colors when wanted. Solvent inks are best suited for printing on white or light colored materials because ink is not as vibrant when printed on darker colored surfaces.

Toner

Laser printing is a complex, technological marvel. The process of sticking powdered toner to a substrate seems like something out of a science fiction movie. Toner, which is comprised of a fine polyester or polymer powder, is adhered using static electricity, then melted into the material using a heated roller. Because toner printing uses a heated roller, heat-sensitive materials are unable to be printed on.

Images and text are arranged on the material using a laser, which indicates where the static charge will adhere the toner. It’s a futuristic process that produces vibrant and permanent printing. Colored toner is arranged in a CMYK (cyan, magenta, yellow, black) format, which provides for a large spectrum of available colors for printing. Photos printed using colored toner are not as clear as photos printed by a UV process because of the precision of ink over toner.

Using toner-based laser printing provides for rapid and economical printing. The rate at which toner can be adhered, dried, and printed is faster than traditional inkjet, solvent and UV printing when printing in black and white. Colored images print slower than black and white does with laser printing. The amount of toner used to print is less than what would be required for inkjet printing, making for longer-lasting cartridges.

Toner printing also lends to a higher-quality image because of the precision of the laser in aligning images and text. Laser printers are more expensive than traditional inkjet printers. Toner is commonly used for printing on paper for documents and publications.

Our Choice

We mentioned in the beginning that we implement UV ink on the majority of our signs. But, comparing it with solvent ink, you may see a lot of similarities between the two. However, there are subtle advantages to UV ink which we feel make our signs the highest quality. The vibrancy of the ink and permanence of the design give us reason to use UV ink. The instant curing property of UV ink also allows us to produce high volume signs in a short amount of time without decreasing quality. We believe that this ink is the best for consumer and business signage, providing for a product that will last for years to come. If you’re wondering what ink is used on a specific sign or material, each product page will list the ink and printing process. Any further questions about our printing methods can be directed to support@signs.com, or gives us a call at 888-222-4929.