The printing industry is full of techniques and tricks to help create unique, one-of-a-kind products. At Signs.com, we implement special cutting techniques in our printing production process to produce your signs to your exact specifications. If you’re looking to deviate from a standard rectangle or square sign, we provide custom (previously known as contour) and custom with border (previously known as halo) cut options on many of our custom signs which allow you to customize your sign shape to the way you want it.

The shape of your sign is up to you as the customer. Sign shape options include:

- Square or rectangle

- Circle or oval

- Rounded Corners

- Custom

- Custom with Border

As we focus on custom and custom with border sign shapes, you’ll learn the difference between these two options which will allow you to create a sign that works for your needs. We’ll also highlight a unique cut, known as die cutting, which is also widely used within the printing industry.

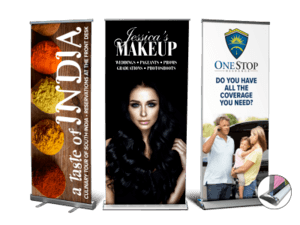

Custom (Contour) Cut

Making a sign that is cut to a specific shape or along the exact edge of a design is achieved by using a custom cut. This cut is achieved by using a digital cutter or router, which creates a precise cut (sometimes referred to as a contour cut) along the edge of your design. Your sign will be printed before cutting to ensure that your design is cut to the exact edge of your design.

Custom cut can create virtually any shape or design, the only limitation is that any cut portion of your sign must be at least ¼” in width. If cut smaller, the integrity of the sign structure would be compromised. The custom or contour shape option is perfect for creating signs without an excess border or background. Some of our most popular signs, including aluminum, plastic signs, acrylic, and magnets can be cut to shape by selecting the custom shape option when creating your sign.

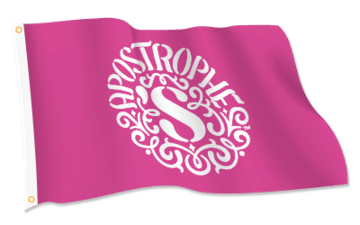

Custom With Border (Halo Cut)

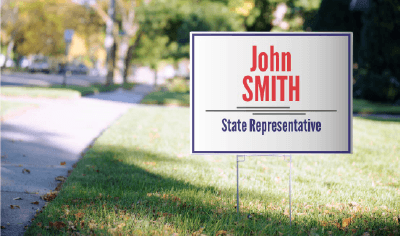

Similar to the custom shape option, which cuts to the contour or exact outline your sign, the custom with border option (previously known as or sometimes referred to as halo cut) will cut around the edges of your design. What sets this cut apart from a custom or contour cut is the border that is left around the edges of the sign. This border is ¼” – ½” in thickness, which provides a sort of ‘bubble effect’ around the outside of your sign. As you can see from the image below, the custom with border option essentially includes a border around your cut-to-shape sign.

Custom with border provides for added strength in a sign, especially those that have intricate designs that you want cut to shape. If your design has areas that are smaller than ¼” and you want to have the sign cut to shape, choosing custom with border will provide a similar cut to shape effect with necessary excess material to protect the sign from breaking. Though if you have portions of your sign that are extremely thin we’d still recommend you contact us before proceeding. We’ll be able to tell you with certainty whether your desired cut is doable and durable for the long run. If you notice in the image below, you will see the difference between a custom with border (halo cut) and custom (contour) cut sign.

We provide the custom with border shape option on a number of our signs, including brushed aluminum, foam board, and wall decals.

Die Cut

Die cutting is sometimes used synonymously with contour or custom shape cutting but, in actuality, they are two completely different cutting processes. If you’re looking for a custom cut, a die cut will not provide you with the desired results. The die cutting process can be equated to using a cookie cutter to make exact shapes in a material. Like with a cookie cutter, die cutting uses a stenciled (die) design that is made from aluminum, which is pressed on a material to punch out shapes and designs. Think of a hole puncher used to make holes in paper, only on a larger scale with limitless designs that can be punched through materials far more rigid and thicker than paper! Because the die is pressed through a material, this process only works with flat substrates such as paper, thin metal, and plastics. Die cutting is typically used on large-quantity jobs because it can cut to the same shape at high speeds and frequency. Softer materials like paper may not work as well as harder materials, as soft materials may bend or fray when the die is pressed through it.

Die cut products provide for a unique display with decorative flair. This cut provides a see-through or window effect when used. Common uses for this cutting process in the printing industry include decorative envelopes and letterhead, metal stencils, vinyl stickers, and leather products. Die cutting is a decorative technique that is best for smaller sized projects (like those mentioned above). Typically, signage for business and homeowner use is not designed with portions cut out from the center of the material. As such, we do not currently offer die cutting as an option. In some cases, industrial printers use laser cutting to achieve the same result as die cutting.

Making the Cut

Determining which type of cut is best for your sign is up to you and your design preferences. If your sign has intricate details to the design, then custom with border would be best to eliminate excess material without harming the durability of the sign. Simple designs and shapes can be cut using the custom shape option, to give you a clean, streamlined sign. To determine which cut is available for the sign material of your choosing, simply go into our design tool and look undeath the ‘Shape’ option. All available shapes and cuts will be listed. Choosing custom with border or custom shape will cost extra. Selecting the circle or oval option might also create just the right shape for your design. In addition, we also provide a ‘rounded’ cut option on many of our signs, which cuts the corners to a rounded shape to prevent any injuries from sharp corners. If you have any questions about which cut would be best for your sign, please contact us at support@signs.com or 888-222-4929

Updated March 5, 2019